¶ Auto Mesh Bed Leveling Wizard

¶ Tools required

- None

¶ Synopsis

Mesh bed autoleveling is distinct from physical bed leveling, and is complementary to it. You should run mesh bed autoleveling at print temperature (for the material being worked with).

Mesh bed leveling probes multiple points on the print surface and provides correction for minor flaws in the build surface which are present from manufacturing tolerances. The first layers of the print will be adjusted in real time to ensure a tight fit to the countours of the surface.

Over time, these contours will level out, and the system firmware will gradually fade out the adjustments over a height of 20mm.

If you're working with full build plate prints, or the same temperature and material frequently, we recommend running this wizard from time to time.

If you notice first layer problems with your prints, we also recommend running this wizard to see if it corrects the mesh. Remember to run the wizard with the bed set to the temperature you'll be printing at.

If you need guidance on what temperature to set, see the Material Cheet Sheet

¶ Adaptive Mesh

You may find the Adaptive Mesh Leveling option in 3D Labs Studio more useful if you change materials and/or temperatures frequently. It runs before each print, however only probes the area of the bed occupied by the print. This results in a faster leveling cycle and tends to be more accurate with a variable workflow.

¶ Pre-requisites

- Heat up the bed to the temperature required by the material you'll be printing with.

Running the mesh at the temperature you'll be printing with is important as the bed surface changes with thermal expansion.

¶ Instructions

- Make sure the print bed is clear of any objects.

- Wait until the bed reaches the set temperature.

- From the home screen, tap Wizards, then Auto Mesh Bed Leveling Wizard:

- Tap the Start button and let the system probe the bed.

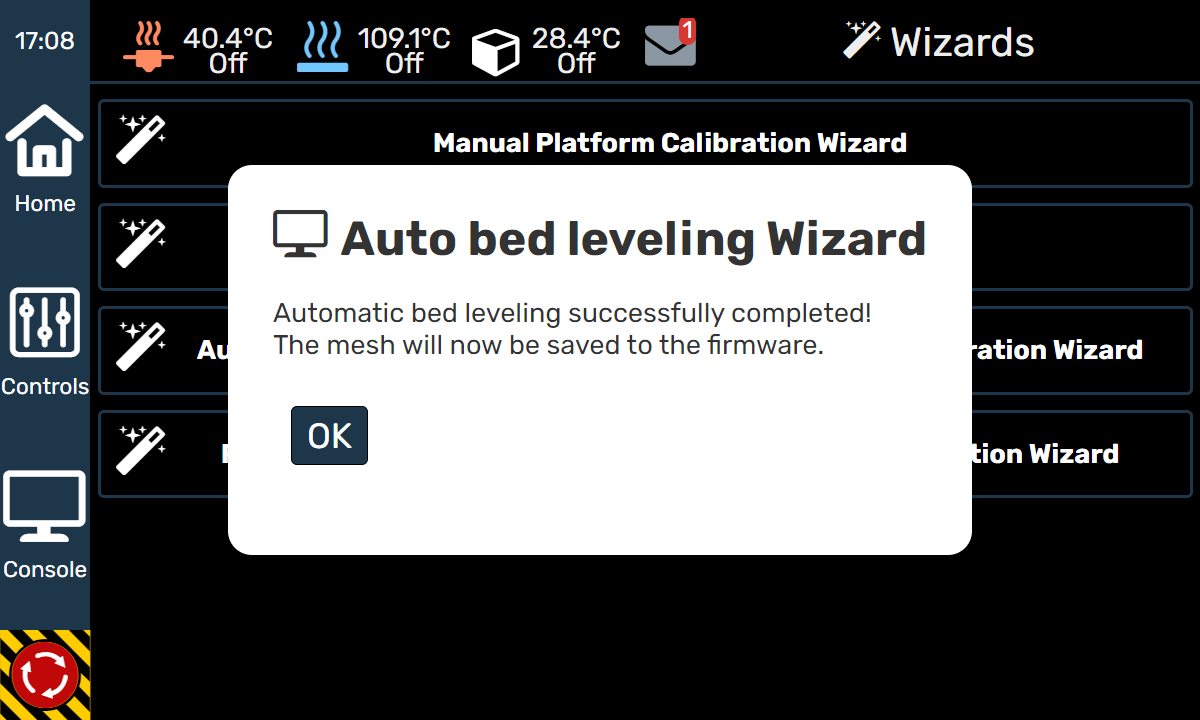

- Once complete, you'll get a notification that the autoleveling has been completed and saved to firmware: