¶ Resonance Compensation Wizard (Input Shaper)

¶ Tools required

- USB cable (included in toolbag)

¶ Synopsis

Resonance compensation, or input shaping, is a technique used to cancel out vibrations in mechanical systems. This technique allows for much faster print speeds while maintaining accuracy and minimizing ringing artifacts.

Running the resonance compensation wizard per the maintenance schedule will identify problematic resonance frequencies in the printer, and optimize the firmware for higher speed printing.

Any time belts are tightened, mass is added or removed to the print head/gantry, or every 200 print hours, we recommend running this wizard.

¶ Instructions

-

Open the lid of the 3D printer.

-

Make sure the bed is clear of any objects.

-

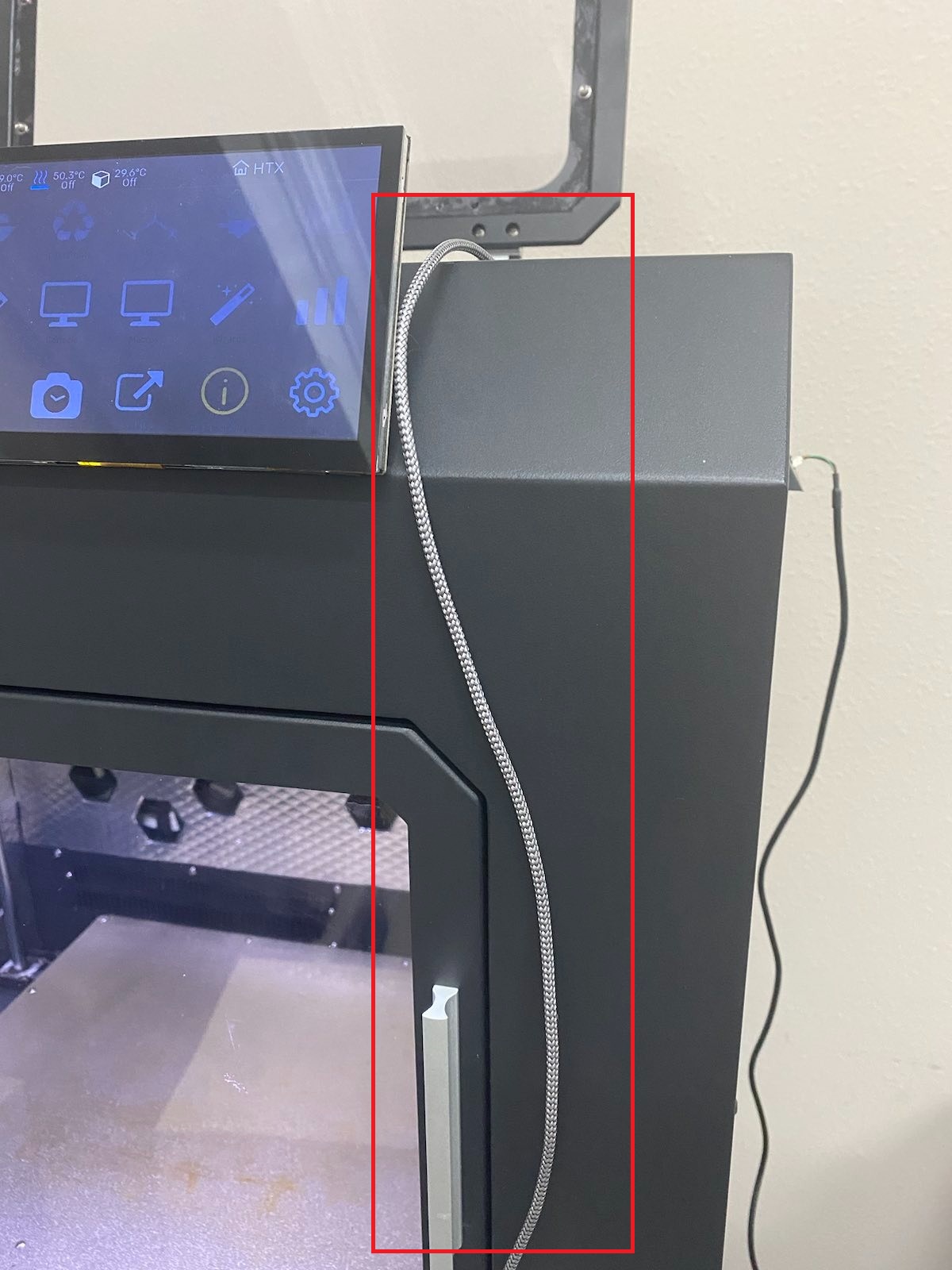

Plug the end of the USB cable into the port on the front of the printer.

-

Route the wire as shown up and through the open lid. Leave the printer lid open.

-

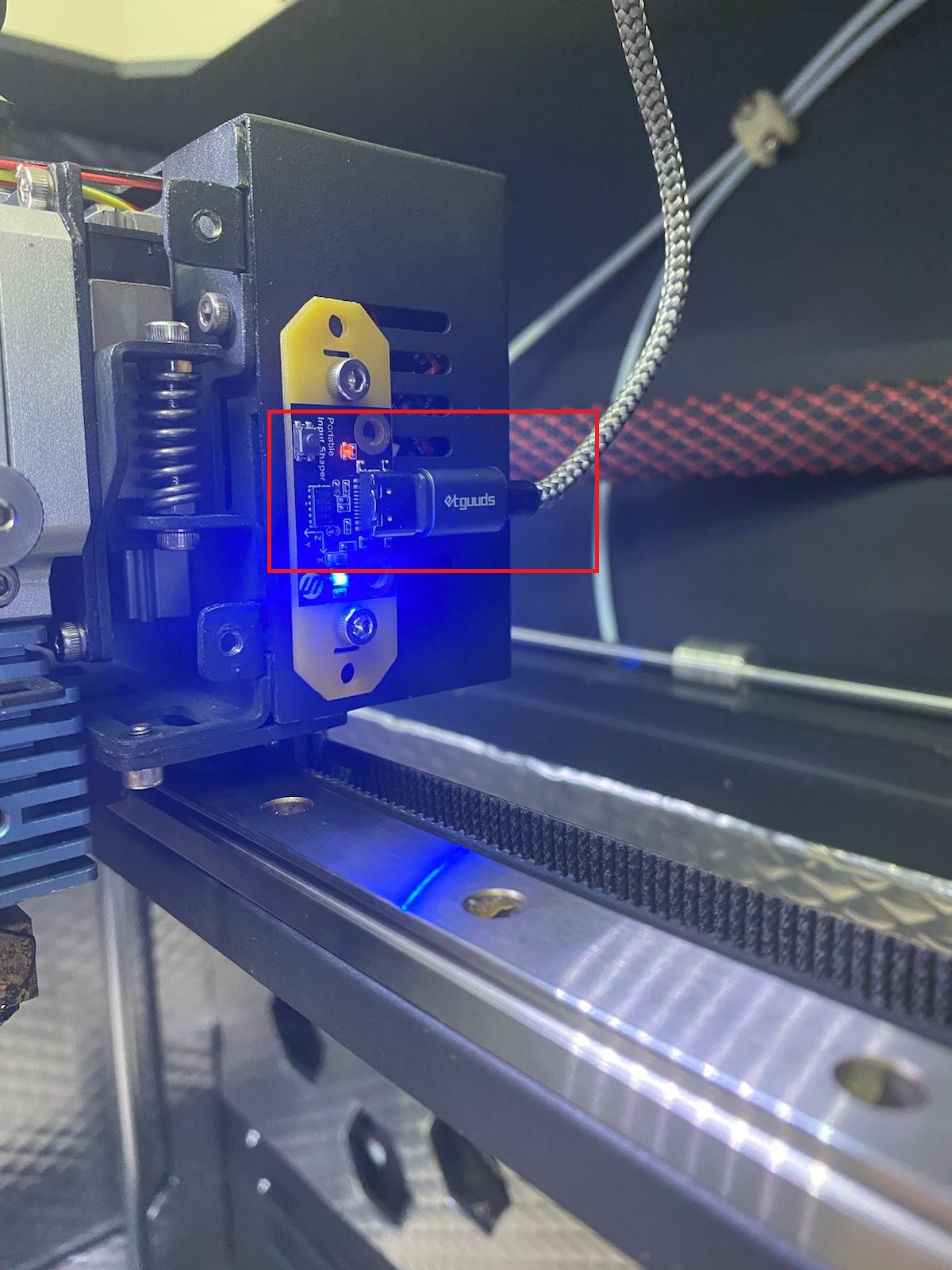

Plug the other end of the USB cable into the accelerometer module.

-

The system will autodetect the module and initiate the Wizard.

-

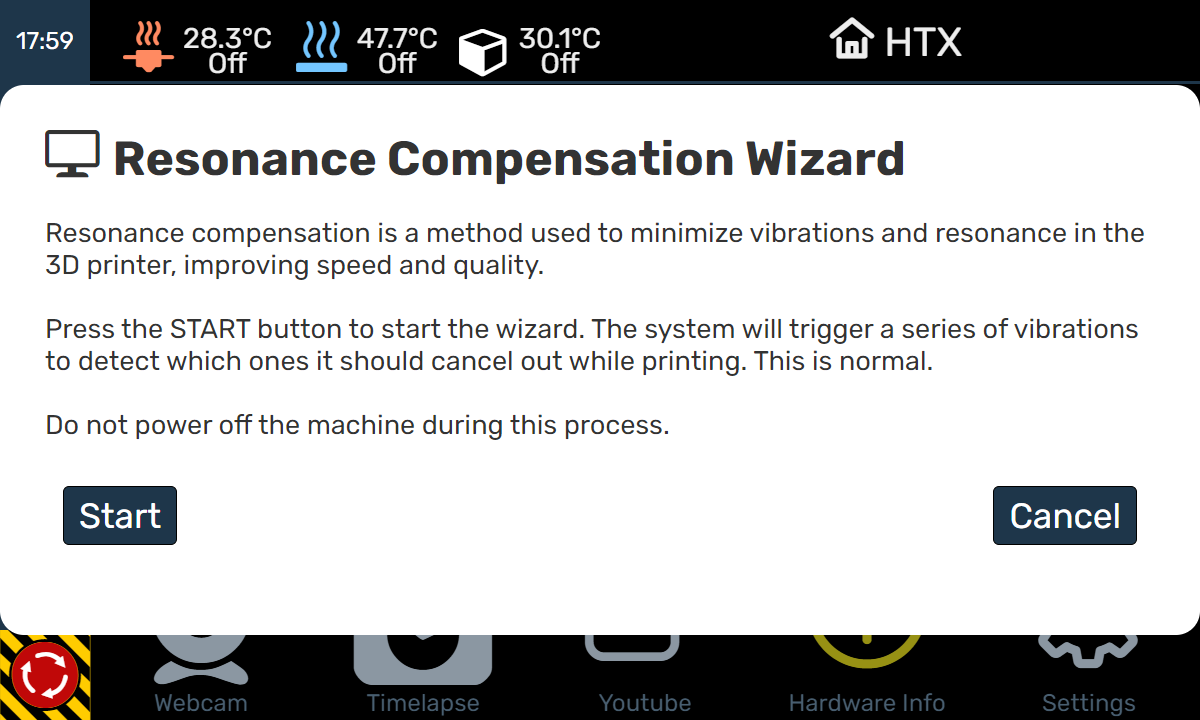

Press the Start button to initiate the wizard.

The machine will make some extreme vibration sounds during the tuning process. This is normal and will not damage the machine.

- The system will home and run the tuning process. This takes approximately 10-20 minutes.

- When complete, unplug the USB cable at both ends and you are ready to start printing.

Important

Failure to remove the USB cable can cause damage to the accelerometer module! Make sure to remove it when done and make sure to unplug it from both ends before using the printer.